Digital Twin & Virtual Reality

Digital Twin & Virtual Reality

with COMOS

COMOS – Making Data Work

COMOS provides the process industry with a seamless flow of information based on a globally consistent database – delivering a common view of data across all disciplines and through all phases of the plant lifecycle.

This is possible thanks to the systematic application of object orientation in our groundbreaking software solutions. Plant engineers and operators have access at all times to data that is always up-to-date – in real time, independent of time zones. That creates the basis for maximum reliability in decision-making, which allows for considerably greater productivity, efficiency, and flexibility in all processes.

Integrated Collaboration Among All Disciplines Over the Entire Lifecycle:

Empower Your Data Value

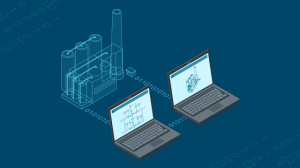

...with Automation Digital Twin

Using the Automation digital twin of the COMOS software solution, automation data can be read out of the process control system and imported to COMOS to be graphically displayed, consolidated, and made available for further engineering. COMOS uses this data to support the creation of the plant’s digital twin, a fast and reliable migration, and updates to the process control system – all with one single solution.

...with Intelligent Mobile Maintenance

The integrated COMOS software solution and the COMOS MRO (Maintenance, Repair, and Overhaul) module provide a single system where management, planning, and organization of operation and maintenance, including plant documentation, are performed. This solution also permits the simple management of error messages in plants. Using the digital assistant implemented in COMOS, maintenance orders can be efficiently processed. Linking to the Asset Information Management System enables data and documents to be read and edited on site.

...with Smart Data For Brownfield

Using a central data platform, COMOS ensures consistent information and a seamless flow of all project-relevant data over the entire plant lifecycle. The COMOS solution for brownfield enablement allows you to quickly record, organize, link, and visualize large volumes of data and documents. The digitized data forms the basis for the digital twin of the brownfield plant. The "Digital twin" is a well-founded basis for measures to increase the efficiency of the plant and greatly facilitates the conversion or expansion of existing plant components.

...with COMOS Modularized Engineering

COMOS makes it possible to consistently implement modular engineering for all disciplines. Using smart templates in sectores like the chemical industry makes engineering and design extremely efficient. Bidding can be prepared quickly, based on a clear cost calculation. By using Modularized Engineering, over- or under-engineering can be drastically reduced. With the standardized modules, customer requests are individually and precisely implemented. Even regulatory requirements (compliance) are reliably met. With COMOS Modularized Engineering, over- or under-engineering can be drasticaly reduced and you can build up a solid knowledge base in the long term.

...with Consistent Process Engineering And Design

One of the most important tasks for the Front End Engineering Design (FEED) phase lies in producing an initial cost calculation and a clear representation of the process flows. COMOS enables an efficient Front End Engineering Design (FEED) as a basis for the initial cost estimate. Block-flow diagrams clearly depict entire processes and serve as the basis for efficiently creating process flow diagrams (PFDs).

...with Compliant Data And Document Management

COMOS enables you to use a uniform database as a source of information for all phases of the life cycle of your plant. In this way, both process speed and plant safety can be significantly increased. The COMOS PQM (Project Quality Management) software solution was even expanded to meet the special requirements of the pharmaceutical industry. Safety and compliance workflows, approval processes and data mapping are always in compliance thanks to an integrated electronic data and document management. The solution permits efficient data and document management - consistent, paperless and mobile.

...with Virtual Plants

Going offshore online - COMOS makes this possible. With the virtual plant generated in COMOS, operators can familiarize themselves with their future working environment during commissioning. During training, the technicians can move freely through the virtual plant, communicate with one another and work on various scenarios. For the technician this means that they does not have to be on-site on a potentially dangerous offshore platform instead, they can plan, visualize, and simulate maintenance activities ahead on time onshore.

End-to-End Plant Management

Data Handover and Visualization

Ensure smooth data transfer and reliable commissioning – with COMOS and COMOS Walkinside

Asset Integrity Management

Achieve maximum profitability thanks to end-to-end Asset Integrity Management – with COMOS Platform, MRO, Shutdown, and Inspection.

Plant and Process Modernization

Ensure that your technology for plant and process modernization is completely up-to-date – with COMOS.

Virtual Reality, Field Operator Training

Create efficient, immersive training sessions for your employees in a virtual plant – with COMOS Walkinside.

Plant Operation

Enjoy global networking and work on the move - with COMOS PQM and Mobile Solutions.

Your Advantages With Comos

Optimization of plant availability through a consistent data base at anytime

Efficient planning, execution and analysis of maintenance activities

Cost reduction of the entire plant lifecycle

Higher safety and competence management through virtual training

Support with regulatory requirements through always up-to-date plant and project documentation

Mobile access to all plant information directly in the field

“Taken from the Siemens website.”